Joining, welding & connecting profiles

We ensure strong connections

We join together what belongs together – and create functional, lasting solutions from steel, stainless steel, and non-ferrous metals.

With custom profiles from Welser, you can be sure that the material and connection type are properly matched and capable of withstanding the required loads.

As a reliable system partner, it is our claim to constantly increase the level of service for our customers and to make further processing as easy for you as possible.

Added Value

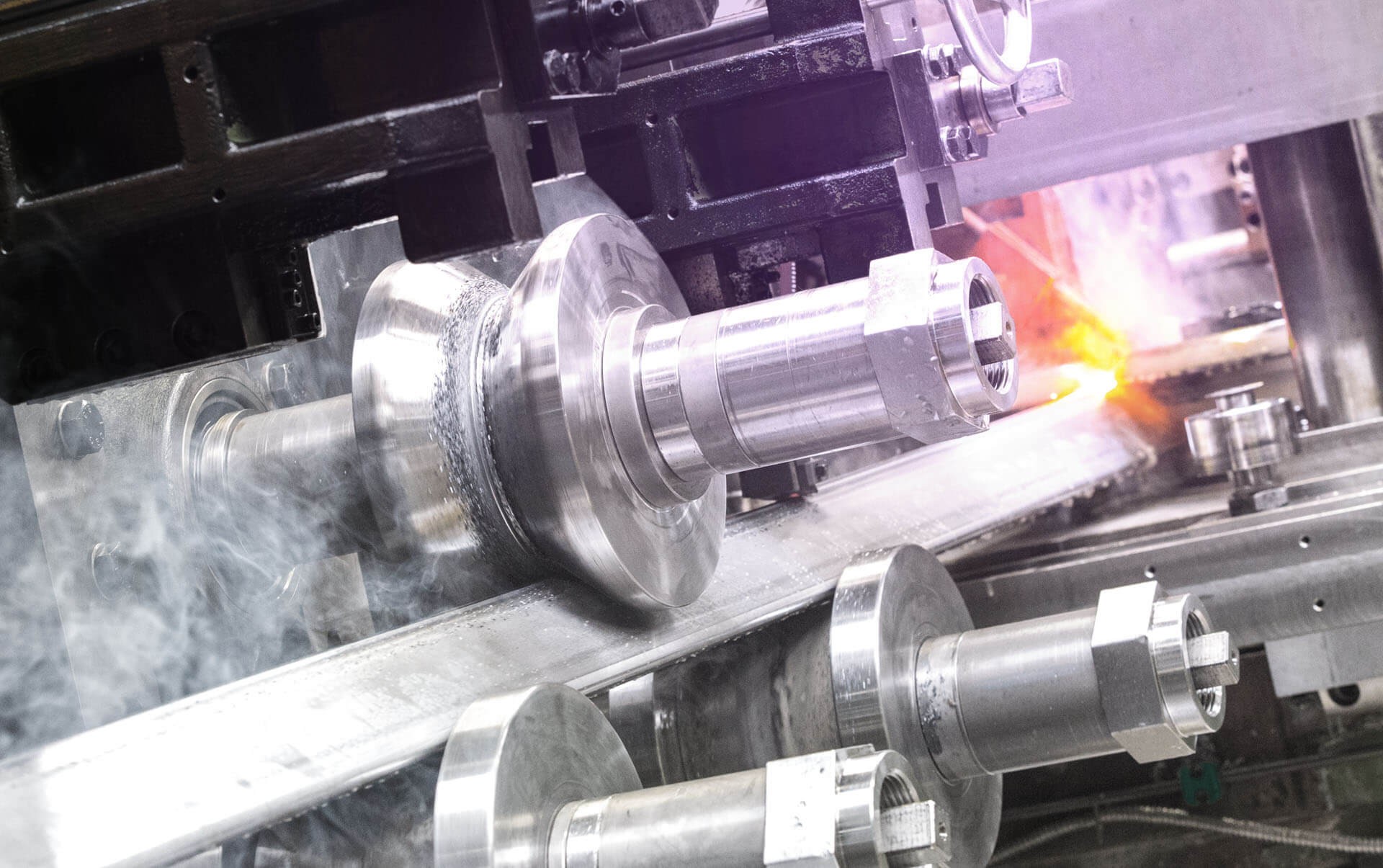

Where the manufacture of welded profile cross-sections – i.e. tubes – is concerned, we have many years of experience. Back in 1980, closed profiles were added to the product range of Welser Profile and their manufacturing process has been continuously optimized ever since.

We are able to connect different materials to each other by using the most efficient joining technologies.

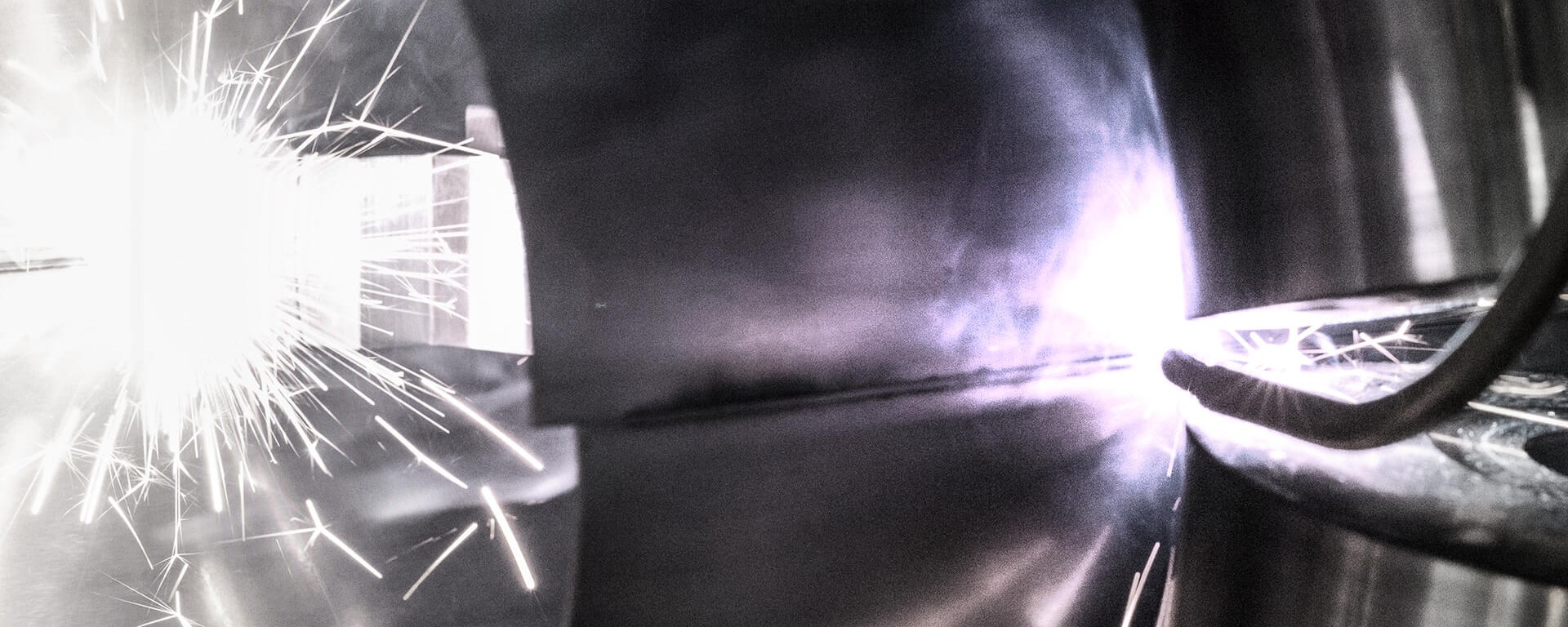

Laser welding:

- for a continual weld – with or without filler material

- to create a multi-layer weld bead. It’s also possible to produce two separate weld beads simultaneously.

- to produce single and multi-chambered profiles in one integrated process

HF welding:

- Inductive (contactless)

- Planing of the weld face, and if required, also the inner weld bead

- In-line re-galvanising of the weld bead for a completely corrosion protected profile

Shielding gas welding:

- for stable, permanent connections

- Robotic welding systems guarantee high reproducibility for excellent quality control

- Weld tests can be performed for bespoke customer requirements

Spot welding:

- without the need for any seam preparation and reworking

- simple to automate

Other joining methods:

- Riveting

- Clinching

- Pressure joining

- Bonding

- and many more

Higher load capacities and expanded functionalities can be achieved through the patented method of “pull-through riveting”.