Roll forming

... the most important process in the manufacture of roll formed profiles and at the same time the most affordable way to manufacture a profile with;

- strip thicknesses from 0.3 to 8.2 mm

- strip widths up to 1,000 mm

- profile lengths up to 27,000 mm

- profile heights up to 320 mm

in large quantities (from approx. 5,000 linear meters) and with high precision. It is highly cost-effective since traditional downstream processes can all be integrated into the one roll-forming process, so steps like punching, embossing, clinching and adding thread inserts no longer need an expensive secondary operation.

A wide range of steels, stainless steels and non-ferrous metals can be roll formed.

Roll forming

What happens during roll forming?

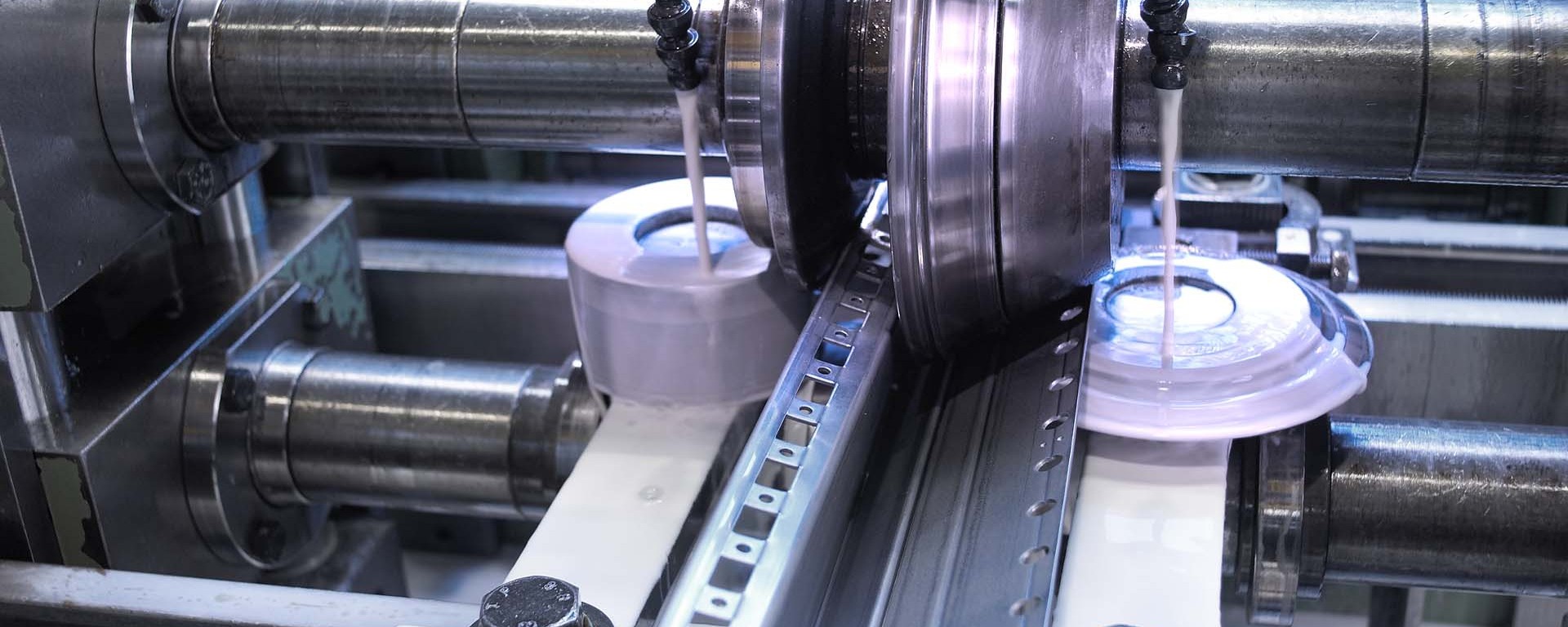

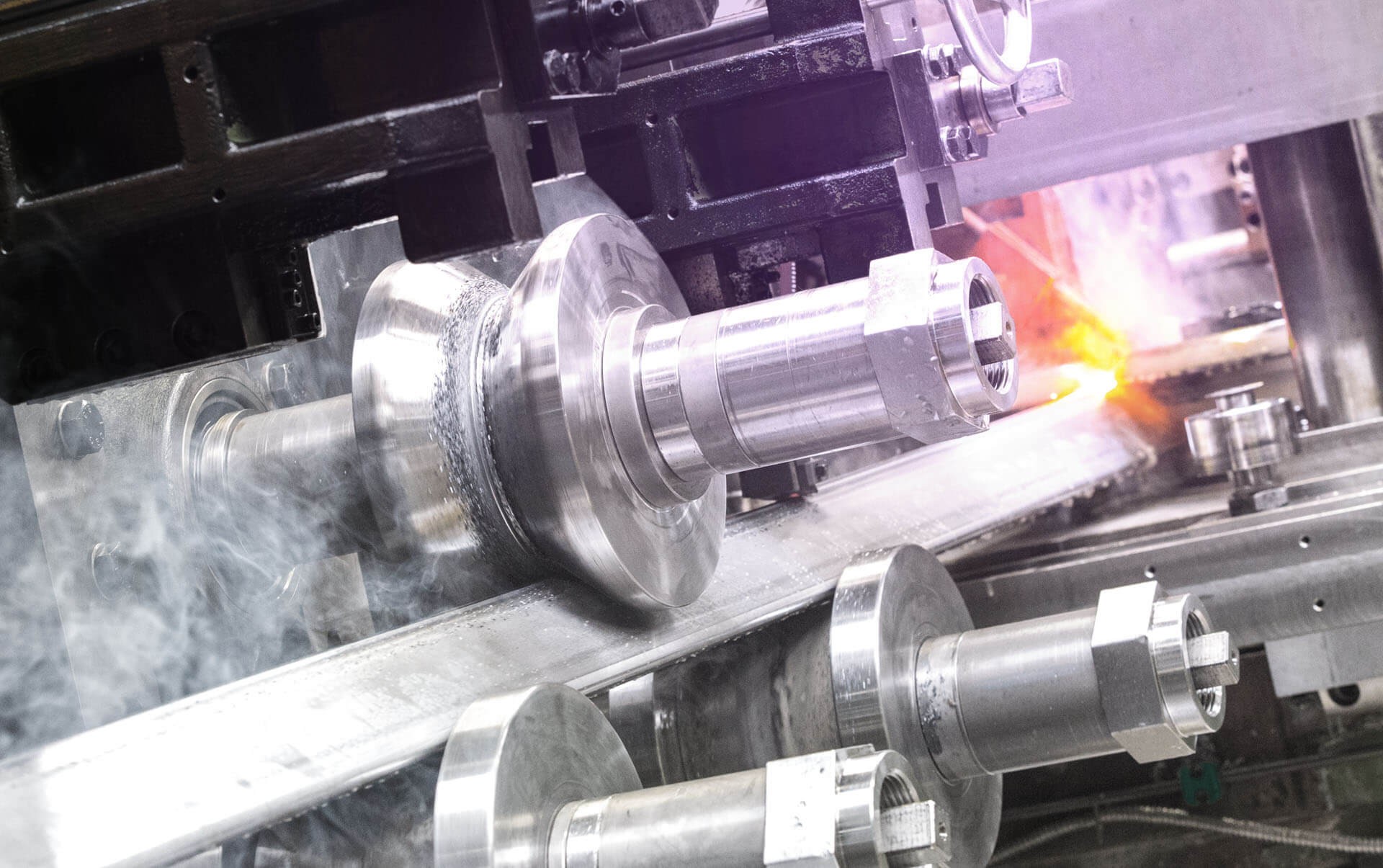

The input material is a flat strip of steel, stainless steel or a non-ferrous metal of high strength, which is mostly wound in coils of different widths. The process of roll forming (also referred to as cold rolling or roll profiling) involves passing this strip through a sequence of modular pairs of rollers and forming the desired cross-section at room temperature. Each pair of rollers performs a further step in the shaping until the desired profile shape is achieved.

The advantages

- Material properties remain practically unchanged, and in some instances are even improved.

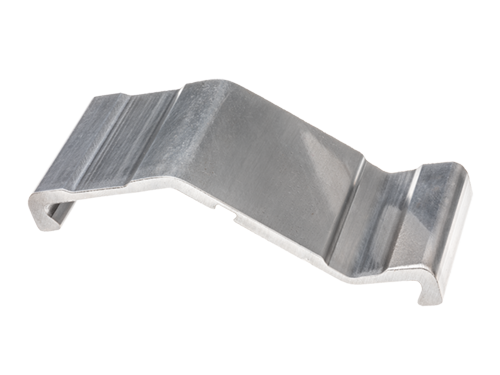

- Better functionality: roll forming enables more complex cross-sections to be created than conventional sheet metal machining.

- Variety of cross-sections: our in-house tool shop and the extensive range of machines bring flexibility in terms of change, response times, etc.

- Positive life-cycle-assessment: Forming at room temperature, a high material utilization and excellent recyclability makes roll forming a particularly energy-efficient process.

In this way,

- we increase your quantities and margins

- we simplify the automated further processing and your production process.

High-tensile steel instead of extruded aluminum

Is your extruded aluminum profile no longer strong enough?

A roll formed Welser profile made from high-tensile steel, stainless steel or non-ferrous metal is the answer.

We provide an economic alternative if your aluminum profile does not meet the tight tolerances or requires costly further processing such as tapping or the placing of punch nuts.

Roll forming instead of Press-braking

Are you still producing your profiles using a press-brake, but need several thousand meters of a certain profile?

We show you that large quantities and constantly tight tolerances are not mutually exclusive, even for extra-long profiles.

What are roll-formed profiles?

We manufacture

- custom profiles, profile tubes or entire assemblies

- perforated or unperforated

- straight or curved

- with the tightest tolerances and enhanced functionalities

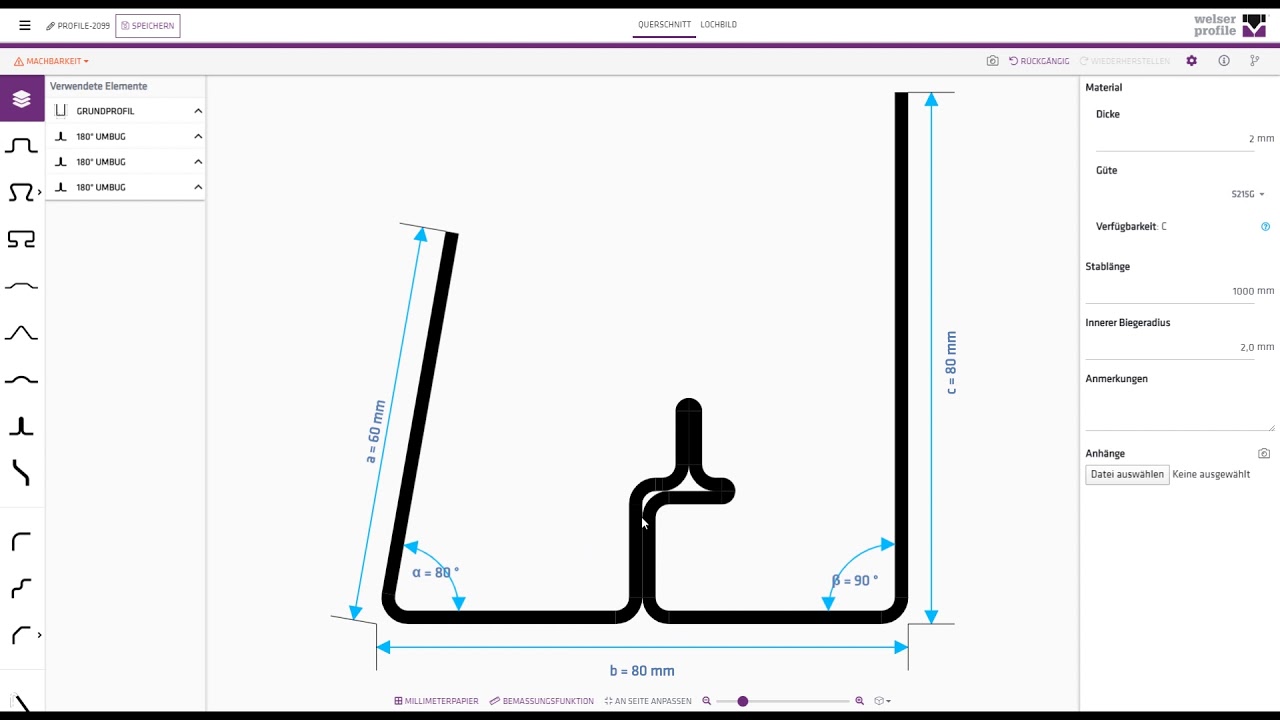

Are you wondering whether your idea for a cross-section is achievable?

Configure your own steel profiles and see for yourself how the complex shapes can be achieved through roll forming.

Does your application demand even more complex cross-sections? We make it possible because we have taken roll forming to another level and also produce strip thickness-optimized, variable-height profiles or linear flow split profiles:

Why Welser?

- because we have more than 360 years of experience in the metal industry

- because we have already developed and manufactured over 24,000 different cross-sections for our customers and are able to reproduce these with consistently high quality

- because we are a global leader in the technology for roll forming custom profiles and offer you the possibility to produce larger quantities while improving your margins

- because we are specialized in accompanying you throughout the entire process of creating your custom profile – from idea to series production readiness.