Extrusions or steel roll forming

Aluminum extrusion or steel roll forming?

Roll-formed steel is the material of choice when an extruded aluminum profile can no longer meet your design or functionality requirements.

As your designs evolve, it may be that your aluminum extrusion will no longer cope with the higher forces you wish to apply to it. Or to make it work, it’s becoming too thick and heavy. Or perhaps the extra work involved along the length of your extrusion to create the ‘plug & play’ part you are looking for is getting too costly.

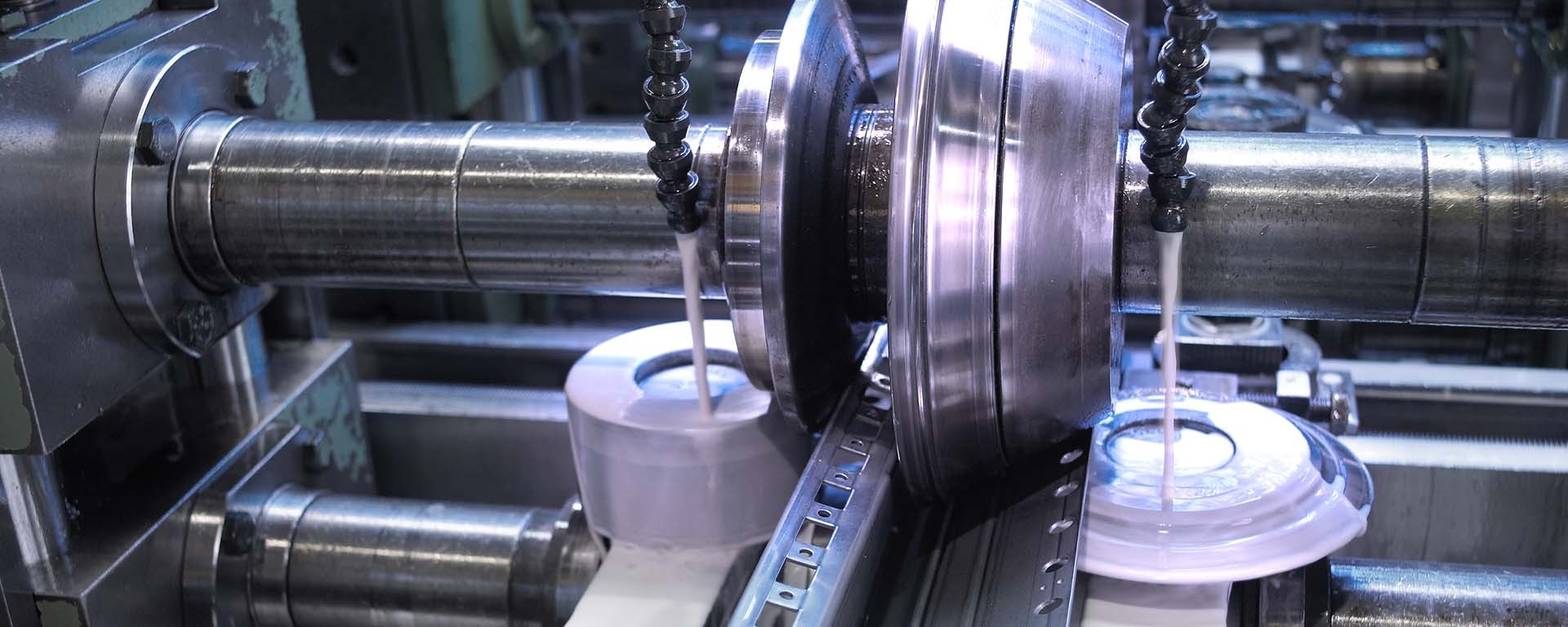

Our roll-formed steel or stainless steel sections combine the advantages of using a stronger metal with the ability to add features into an incredibly cost-effective, single process.

Advantages of roll-forming compared to extrusion

- Very strong/hard metals can be roll-formed, for example steels up to 1700 N/mm2 yield.

- The metal strip is formed at room temperature, maintaining the properties of the feedstock metal.

- As the metal strip is gently folded into shape, corners are generally more rounded than the sharp corners created when extruding.

- Multi-chamber designs are created by integrating inline welding technology to the roll-forming process.

- Very tight tolerances can be consistently held along the length of the roll formed section.

- Painted an pre-coated steels, as well as material with a removable protective coating can be roll-formed, so that an aesthetically pleasing surface finish is achieved without any additional treatment processes.

We can do even more for you:

- The wall thickness in a roll-formed section is usually fixed (it is the feedstock strip thickness), although we have certain processes that can be applied to modify this rule, including combining profiles of different thickness, and even more specialized metal forming techniques.

- Additional features, such as threaded holes, embossing, captive nuts or many others can be added along the length of the metal section on the roll forming machine itself, saving the need for more costly additional downstream processes.

- Roll forming tooling is more extensive than extrusion and can therefore cost more. However, we only ever pass on a shared tooling cost, which lowers the investment needed to begin roll-forming. Tooling costs can also be offset by the ease of adding features along the length of the roll-formed section when compared to achieving the same result with an aluminum extrusion.

Why steel?

- Rolled steel exhibits outstanding properties, for example better strength and stability, a lower co-efficient of thermal expansion and a higher elastic modulus (particularly useful if connecting to glass)

- Steel offers an almost limitless lifespan

- Weight savings through the use of high & ultra-high strength steels with load optimized thicknesses, and the potential to subsequently integrate additional functionality

- Large batch quantities leading to very economic production

- A wide variety of potential coating and surface treatments

- Rapid response times and process optimization through in-house tooling design & manufacture as well as process simulation