History

A family company in the 11th generation

The Welser family has been processing steel for 11 generations. We can trace the company’s roots back to 1664 at the “Haus in der Au” in Ybbsitz – not far from today’s Welser Technology Center.

A pan forge back then was the origin of today’s Welser Profile Austria GmbH. At the end of the First World War, the construction of a punching shop and the switch from traditional hydropower to turbine power heralded the start of a new era for the company. The production of roll formed profiles was added in 1960. This set the direction for the success of the Welser Profile group of today.

A journey through the company’s history

The “Haus in der Au”, the present-day location of the head office, was first mentioned in documents in 1290. This property has been in the uninterrupted possession of generations of the Welser family since 1664. The processing of metal in a pan forge and later in a punching shop laid the foundations for the family company’s long tradition.

Development into the international industrial business it is today began in the second half of the 20th century.

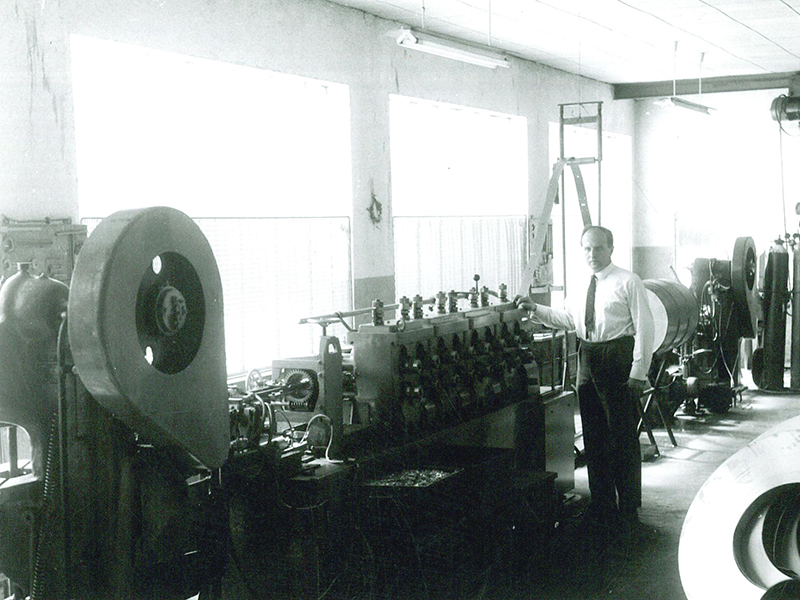

1958

Five employees working under Josef Welser.

1960

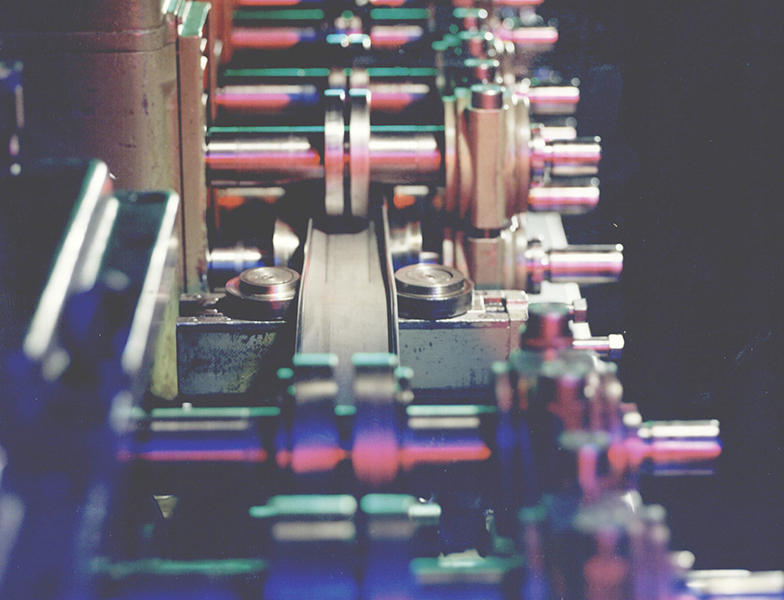

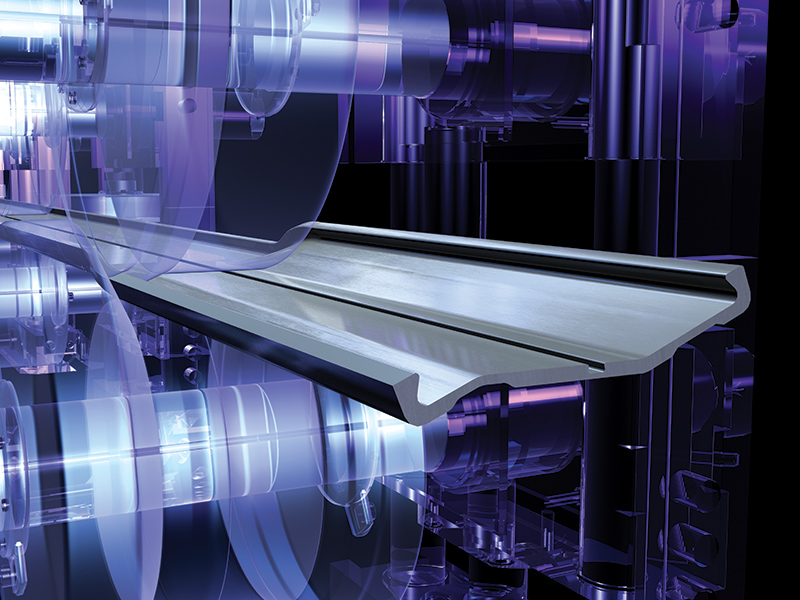

The production of rolled profiles begins. Profile production emerged from the idea to create protective edges for concrete form liners. Instead of punching, bending and piercing these form liners on eccentric presses in seven operating steps, the idea was born to warp edge protection lining on rolling machines.

1961

The company becomes a general commercial partnership (OHG). Komm.-Rat (Commercial Counsellor) Waltraud Welser and Komm.-Rat (Commercial Counsellor) Josef Welser are the managing directors.

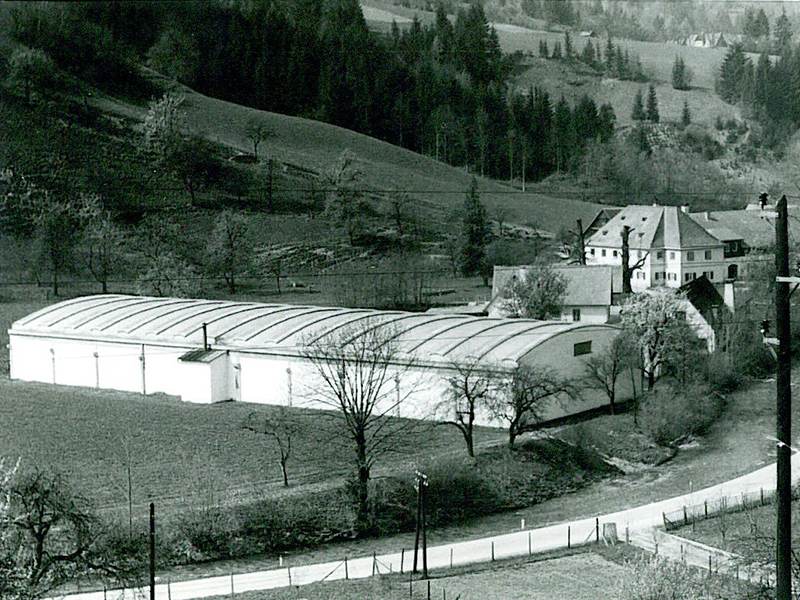

1962

The first production hall is built in Ybbsitz, Austria.

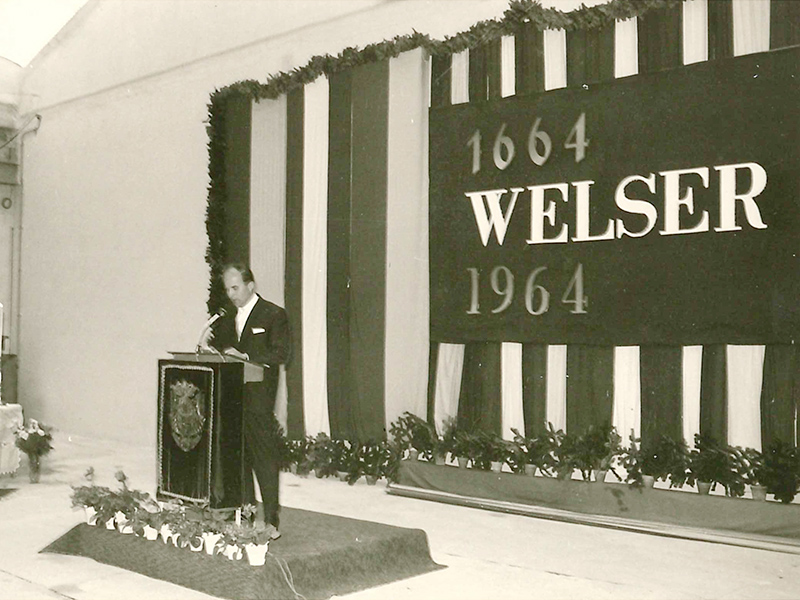

1964

300th year anniversary of the Welser family business. The consumption of semi-finished materials is slightly under 2,000 tons/year. From this material, approximately 2 million linear meters of profiles are produced, with nearly 2/3 exported internationally.

1966

The first expansions to the production hall are made. A separate area is established for the construction of tools and equipment. From here on, all of the tools and equipment required for production are designed and manufactured in-house.

1969

Semi-finished material consumption has already reached 6,000 tons/year. These materials are already being made into approximately 5.5 million linear meters of profiles.

1970

A new office building is built with construction rooms. At this point in time, the company is already creating 1,200 different profile cross-sections. The company has entered the IT age. Financial accounting, payroll and material management are the first areas utilizing electronic support.

1971

A modern company logo takes the place of the centuries-old emblem (a key). The new logo symbolizes continuous roll forming in which rollers are used to shape metal strip into profiles.

1972

Another company location is founded in the town of Gresten, where a new production hall is built. This enables the old iron market of Gresten to re-enter the iron industry.

1974

This year sees the quantity of processed materials grow to approximately 14,000 tons. After being processed, this is equal to more than 11 million linear meters of profiles.

1975

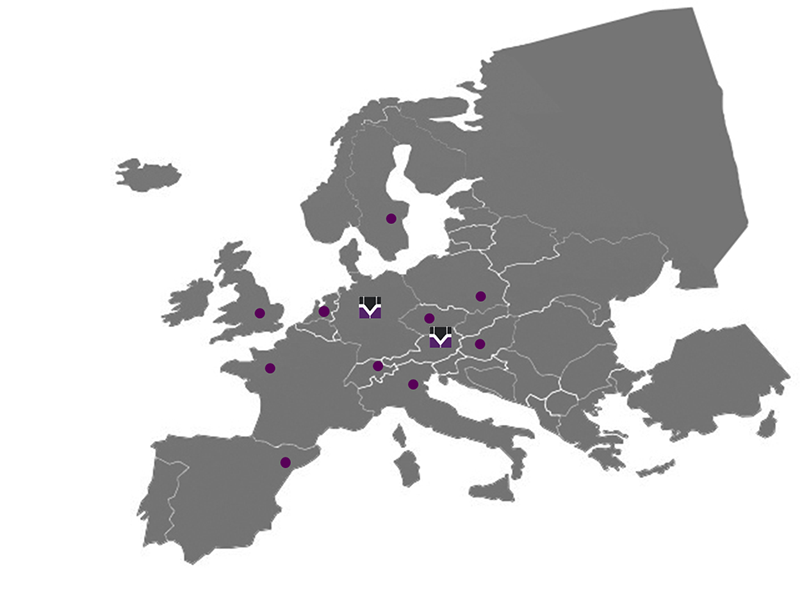

Foundation of the first sales office in Switzerland. The founding of further sales offices follows, signalling the internationalization of the company:

- 1978 in the Federal Republic of Germany

- 1978 in Sweden

- 1986 in The Netherlands

- 1987 in France

- 1988 in Italy

- 1990 in Spain

- 1993 in England

- 1994 in Hungary

- 2003 in Poland

- 2005 in the Czech Republic

1980

Expansion in Austria also gathers pace. Two additional production halls are erected in Gresten. In addition to open profiles with complex cross-sections, welded profile tubes are also added to the production program for the first time.

1985

With the construction of three additional production halls, 41,000 tons/year of preliminary material are now being processed, from which more than 24 million linear meters of profiles are produced.

An office is established in the centre of Vienna for customers in the greater Vienna region.

1986

The plant at Gresten receives a railroad connection. From here on, the necessary preliminary material is delivered almost exclusively by rail. As a result, 2,500 fewer freight trucks are clogging up the roads.

1992

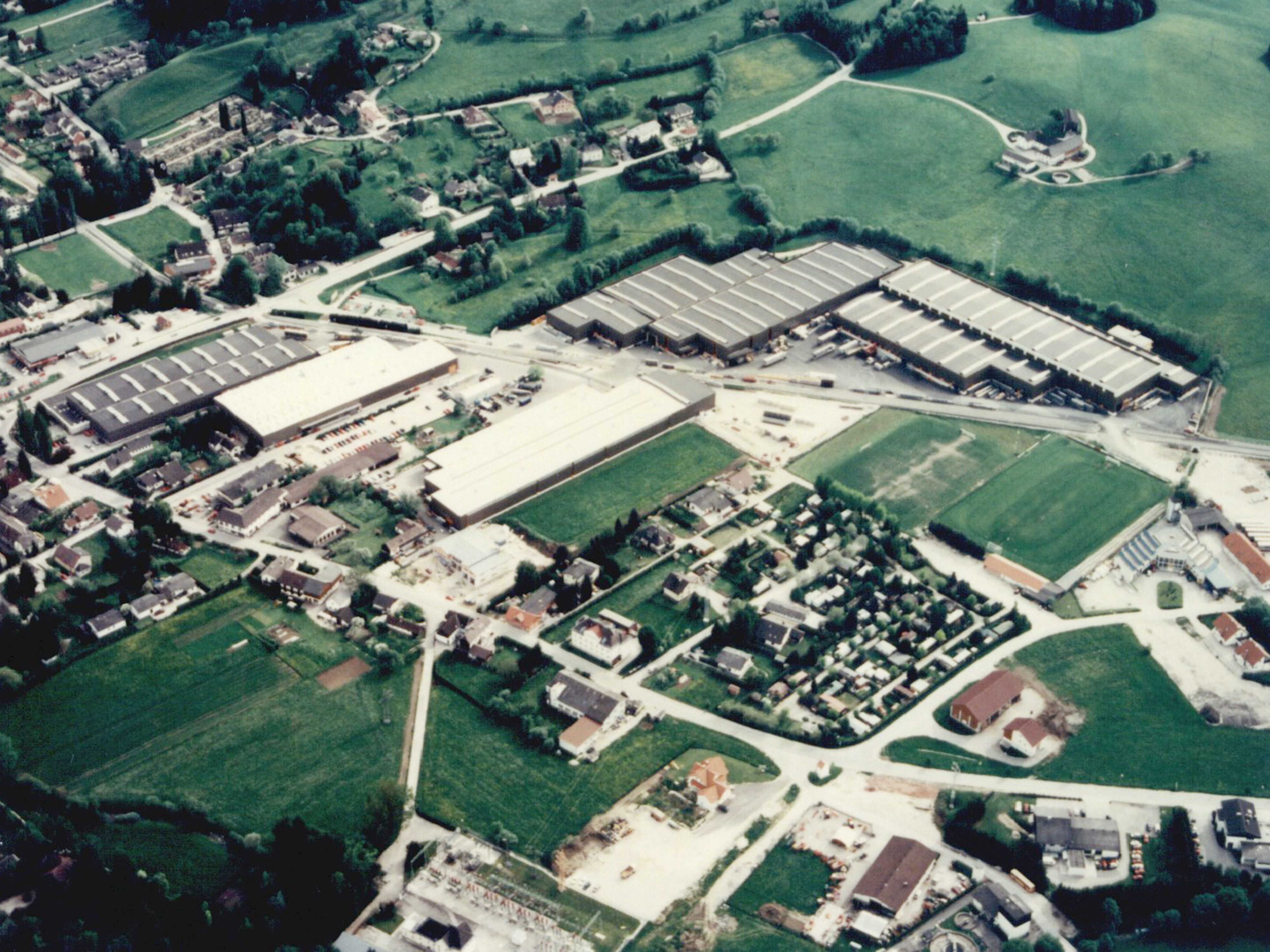

An additional four production halls are built in Gresten. The region of operation (Ybbsitz and Gresten) now covers a combined surface area of approximately 95,000 m2, with a built-up surface area for both locations totalling approximately 39,000 m2.

1995

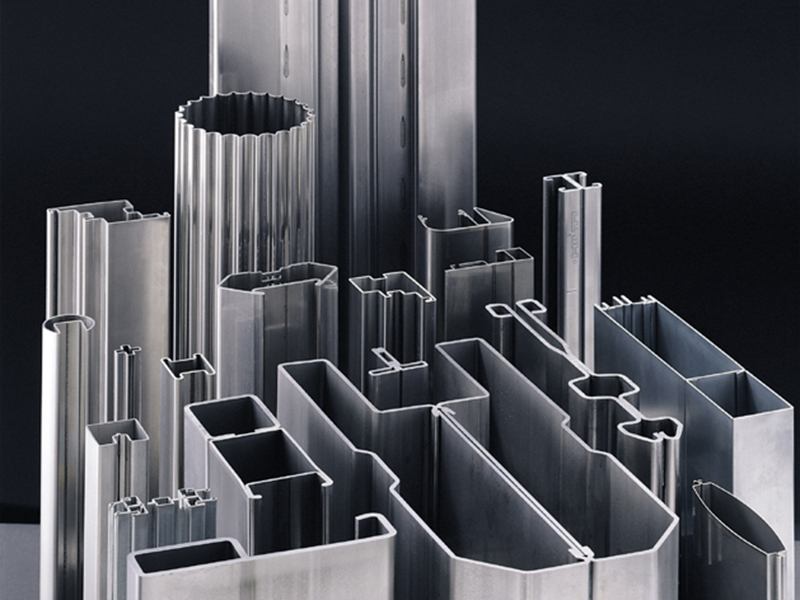

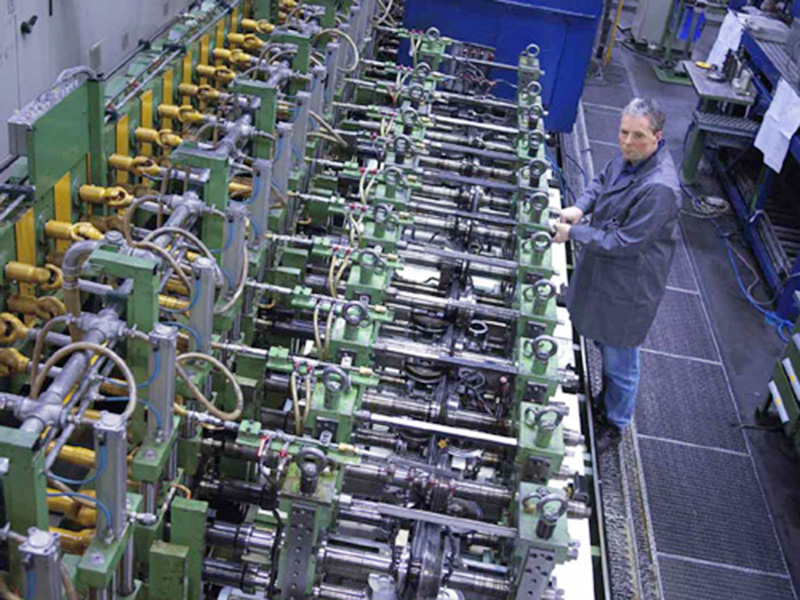

Until now nearly 9,500 different profile cross-sections have been produced on a total of 22 high-performance profile rolling trains, finding usage in nearly every major sector of industry.

At present, the company employs 670 workers, who process 140,000 tons of steel annually.

1997

The 25-year company celebration in the Gresten plant is marked by the largest company expansion to date. With an investment volume of over EUR 36 million, four new production halls are created.

The region of operation for both plants now has a total area of 153,000 m2, with a built-up area of approximately 57,000 m2.

1998

After speedy construction in autumn, the capacity of the Erlauftalbahn is increased (from narrow gauge to standard gauge) and put into operation. This investment brings internal re-organization of the entire logistics and reemphasizes the company‘s environmental orientation.

1999

At the end of 1999, the general commercial partnership (OHG) becomes a public limited company (AG) - 100 % private ownership (Josef and Waltraud Welser).

Komm.-Rat Ing. Wolfgang Welser and Ing. Helmut Welser were appointed as directors.

Two companies in Germany are acquired, the rollforming plant Hoesch Hohenlimburg GmbH in Hagen-Kabel and RP Technik in Wickede with its subsidiary RP PURAL GmbH Riedstadt.

2000

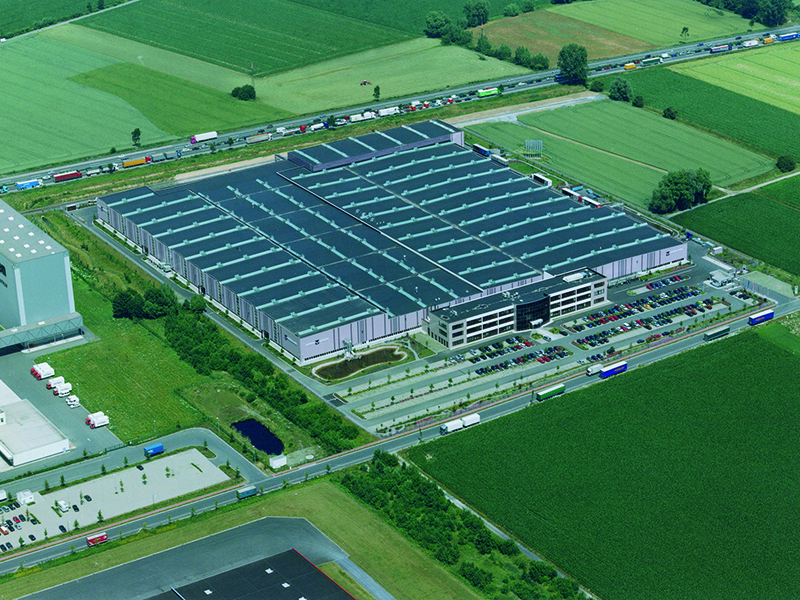

Germany: The newly established operations area of 47,000 m² now offers Welser Profile GmbH in Germany the same production possibilities as Welser Profile AG in Austria. The investment of approximately EUR 72 million enabled close proximity to the production and clear logistical advantages for our customers in Northern and Western Europe.

Switzerland: 25 years of Welser AG.

2002

At the start of the year, a new office building with 744 m2 was completed in Gresten.

2003

The 10th sales office in Poland was founded on May 1st.

November: Successful renewal of certification according to the process-oriented management system standard ISO 9001:2000 by the ÖQS.

The total number of employees has climbed to approximately 1,500. Of these employees, approximately 910 are in Austria, 530 in Germany and 60 at the logistics location in Switzerland and in the nine sales offices all over Europe.

2004

The beginning of a continuous process for extensive company development towards “Welser 2014“ - 350 years of Welser continuously over 11 generations as a family business at the Ybbsitz location.

2005

Founding of the sales office in Prague for the sales region Czech Republic.

Welser Beteiligungs GmbH Germany and RP Technik GmbH taken under the scope of the multi-site certification.

Construction of canopies for halls 5-7 (1,320 m²) at the works in Gresten.

2006

From 11th-13th December 2006, Welser was audited at the sites in Austria and Germany according to the guidelines of the OHSAS 18001 (Occupational Health and Safety Management System) and successfully certified by the AUVA.

The presence of the sales force is strengthened in eastern European countries and Russia.

The logistics centre in Horn (Switzerland) is expanded with halls 3 and 4.

2007

Plans go ahead for expansion in Bönen. The project to construct 9 additional production halls and an office building with full personnel amenities will be carried out in two construction phases covering a total surface area of 87,570 m2.

In an effort to protect the environment, a roof canopy is constructed at hall 5 measuring 580 m2. In addition, canopies come in to use at halls 1-2 (1,360 m2) and halls 12-15 (2,900 m2).

2008

In order to improve the ecological balance, an environmental management system is integrated in to the existing management system. In November the company was audited in Germany and Austria by the “Quality Austria” according to the guidelines of ISO 14001:2004.

In Gresten, Welser is expanded by a further 1,790 m2 with the construction of hall 5b.

2009

The new RP Technik hall was up and running by April.

Production halls 3 and 4 at the manufacturing site in Gresten were expanded (3,140 m2).

The Welser Profile Group experienced a drop in sales as a result of the global economic crisis. The company used the crisis as an opportunity to concentrate on measures for improvement and further training activities.

2010

The Welser Profile Group was restructured on 11th October 2010, in order to ensure the sustainability of the family organisation.

Welser Profile AG in Ybbsitz (Austria) is now registered as Welser Profile Austira GmbH. Welser Profile GmbH in Bönen (Germany) is now registered as Welser Profile Deutschland GmbH.

2011

On 1st January 2011, the group of companies is brought into the „Josef and Waltraud Welser Private Foundation“.

2012

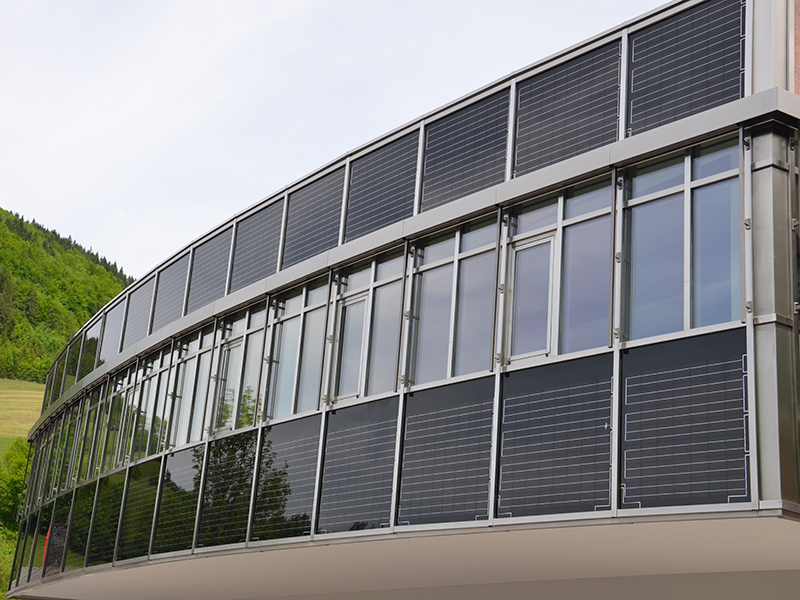

A photovoltaic system is installed on the new office building located at the site in Ybbsitz. In Gresten, a staff area is added to halls 7A and 7B, a cooling system is introduced for halls 1–4 as well as a central heating system for halls 1–16.

Steady growth leads to further expansion at the production site in Bönen. The development covering an additional 9,660 m2 includes the extension of halls 17 and 18 and construction of hall 19.

A new sales office was founded in Istanbul, Turkey.

2013

From September, all customer contracts are processed via the newly founded central sales company Welser Profile GmbH.

A new sales office was founded in Moscow, Russia.

Achieving the production of more than 20,000 unique profile cross sections was clear evidence of the successful performance of the company.

2014

The 350th Year of Welser was a good reason for a big celebration held together with employees, customers and business partners.

The production facility in Gresten was expanded – Halls 5 to 7 were increased by 3,807m2.

2015

An important milestone in the further development of our quality processes is the implementation and certification of our processes to ISO/TS 16949.

Welser AG in Switzerland celebrated its 40th Anniversary together with many long standing customers.

2016

The construction of a logistics building outside the company's premises paves the way for additional storage areas in Gresten, thus reducing traffic load notably. Just-in-time delivery may now be realized in a comfortable way.

2017

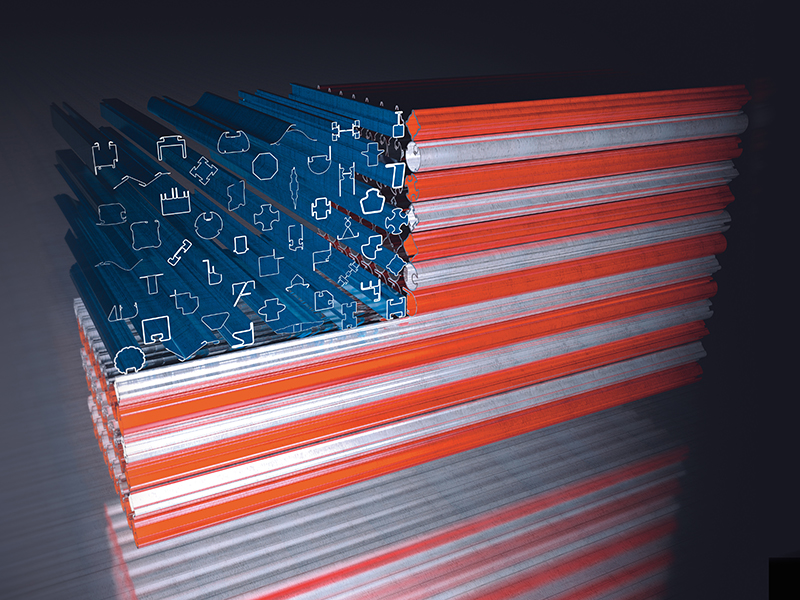

The foundation of our sales office in Chicago in January 2017 is the first important step towards an expansion of the Welser Profile Group into America.

2018

Welser Profile initiates the second step towards America by acquiring the US-producer of costume profiles, Superior Roll Forming. It aims at the best possible supply reliability at the American continent and an increased quality of service.

On 27 February, 2018, Waltraud Welser, founder and co-owner of the Welser OHG and the later Welser Profile Group dies.

2019

Welser Profile opens a modern training facility at its Gresten site, giving even more young people the opportunity to take on an apprenticeship in the metal industry.

On 17th September, we were presented with the 'Award for Excellent Employee Orientation' by EUCUSA Consulting, for our continuous improvement of employee satisfaction.

2020

Covering an area of 7.000 m2, the photovoltaic structure on the roof of Welser AG in Horn, is the biggest in Eastern Switzerland!

A new production hall, complete with an office and high-bay storage area, is constructed in Gresten.

2022

Our 5th manufacturing site – and the 2nd in the USA – is officially open. The company premises covers an area of around 100,000m2 and the profiles manufactured at this site will predominantly be used in the solar industry, storage technology and safety cabs.